Althon supply a large range of Duckbill Valves to mitigate flood risks caused by water backflowing up pipework discharging into rivers, swales and the sea

We supply Duckbill Valves that can be slipped over and clamped onto pipework

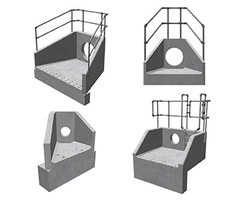

We also supply Duckbill Valves on steel backplates to factory fit to our precast headwalls or other flat surfaces. Duckbill valves are available be flanged ends to mate to flanged pipes of all specifications

Key benefits of Duckbill Valves are as follows

- Reliable backflow prevention

- Minimal bottom clearance required

- 100% elastomer construction eliminates maintenance

- Will not corrode, warp or freeze open or shut

- 1”-2” Cracking Pressure, Low Headloss

- Curved Bill enhances sealing around debris

- Custom built for each application based on pressure and flow conditions

- Available in diameters from 4" (100mm) to 102” (2550mm)

For more information, sales and technical enquiries please contact Althon by email sales@althon.co.uk or by phone on 01603 488700

If you require any assistance or more information please contact us by phone on 01603 488700 or by email sales@althon.co.uk