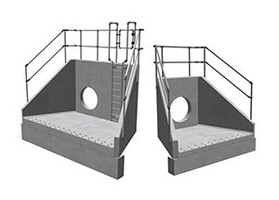

RSFA12D Rectangular Headwall

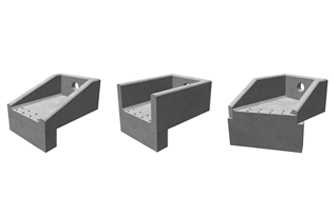

RSFA12D Rectangular Precast Headwalls are Sewers for Adoption compliant precast concrete headwalls for outfalls discharging into ponds, swales, ditches beaches and rivers. RSFA precast headwalls come with the option of two thicknesses of toe, 300mm and 500mm, each of which is available in three depths. Althon RSFA12D rectangular precast headwalls have horizontal wingwalls and are suitable for use with plastic or clay pipework up to 225mm. Althon RSFA12D precast headwall units can be pre-fitted with a range of accessories such as flap valves, penstocks, Kee Klamp® handrails and a selection of gratings depending on the application.

Our RSFA12D precast headwalls are manufactured in accordance with Severn Trent Water Standard detail STD6002. All RSFA Headwalls are cast with the opening in the back wall to suit the size and type of pipe being used at the invert level required. The RSFA12D headwall weighs 1855kg.

We can offer coloured headwalls in 4 colours but the final shade is affected by many influences.

Natural

Cotswold

Agate

Raven Grey

Everglade

Brochures, Datasheets and Installation Instructions for RSFA12D Rectangular Headwall

Free headwall design service

If you cannot find what you are looking for our Free Headwall Design Service can help.